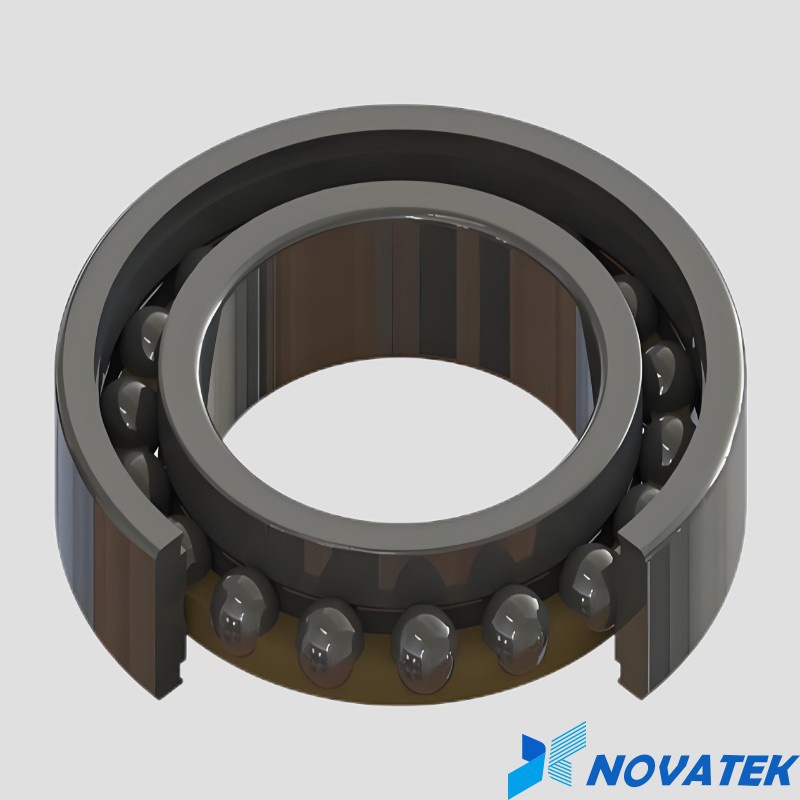

Silicon nitride ceramic ball is a kind of precision ceramics sintered at high temperature in non-oxidizing atmosphere, with high strength, high wear resistance, high temperature, corrosion resistance, acid and alkali resistance and other excellent properties. Its density is 3.20g/cm³, about 1/3 of the weight of bearing steel, small centrifugal force when rotating, suitable for high-speed operation. In addition, silicon nitride ceramic balls are also self-lubricating, suitable for non-lubricating media and high pollution environment.

MATERIAL : Si3N4

DENSITY : 2.8

COLOR : Black / Blue / White

HRDNESS(Mohs scale) : 9

MAX WORKING TEMPERATURE : 1650

Read More

IPv6 network supported

IPv6 network supported