Silicon nitride ceramic bearings can maintain stable mechanical properties at high temperatures up to 1400 ° C. Compared with traditional ceramics, silicon nitride ceramics show higher strength and toughness, and can withstand greater impact and loads .

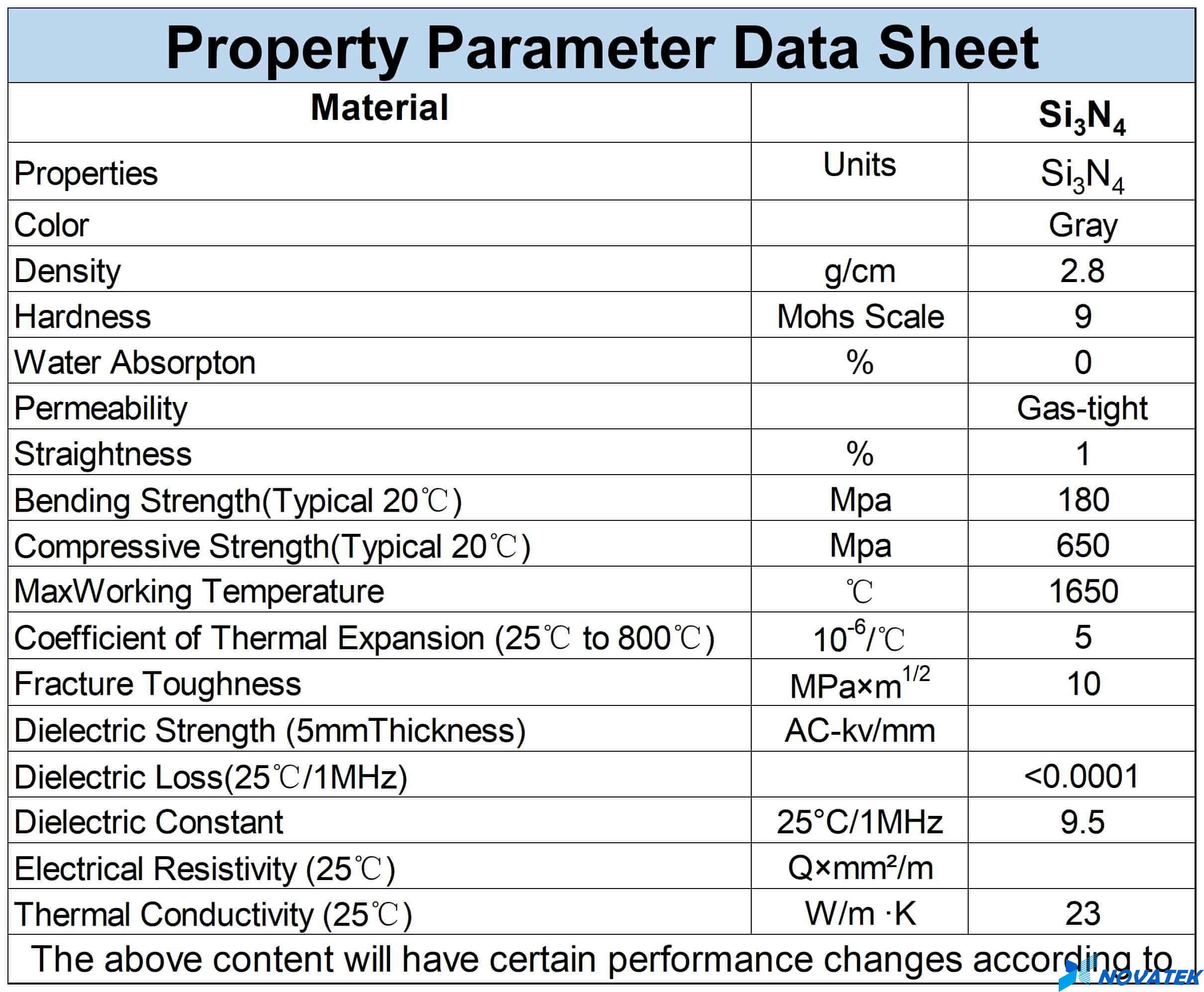

MATERIAL : Si3N4

DENSITY : 2.8

COLOR : Black / Blue / White

HRDNESS(Mohs scale) : 9

MAX WORKING TEMPERATURE : 1650

▼Performance characteristic

1. Excellent corrosion resistance : silicon nitride ceramic tube has good corrosion resistance to most acid, alkali, salt and other chemical media, and can maintain stability in harsh chemical environment

2. Excellent high temperature performance : can maintain stable mechanical properties in a high temperature environment of up to 1400℃, suitable for high temperature gas transport and heat exchange equipment

3. High strength and toughness : compared with traditional ceramics, silicon nitride ceramics exhibit higher strength and toughness and can withstand greater impact and load

4. Low friction coefficient and wear : the high hardness (Mohs hardness 8-9) and low friction coefficient of silicon nitride ceramics enable it to maintain a low resistance coefficient during the fluid transmission process, thereby improving the transmission efficiency

5. Good electrical insulation : silicon nitride ceramics are a good electrical insulation material suitable for applications requiring electrical isolation

6. Excellent mechanical properties : silicon nitride ceramics have high yield strength and fracture resistance, and can maintain stability under heavy load

7. Low thermal expansion coefficient : the low thermal expansion coefficient of silicon nitride ceramics can effectively reduce the deformation at high temperature and ensure the stability of the structure

8. High density : through high temperature and pressure sintering process, the density of silicon nitride ceramic tube can reach more than 98%, improve the strength and wear resistance of the material

▼Field of application

High-Speed Precision Bearings: Used in machine tool spindles, motorized spindles, and high-speed motors to reduce friction and heat generation, extending service life.

Aerospace Bearings: Withstand extreme temperatures (>1000°C) and shock, making them ideal for aircraft engines and rocket propulsion systems.

Wind Turbine Bearings: Applied in wind power generator main shafts to enhance reliability and reduce maintenance costs.

Hybrid/Electric Vehicle Motor Bearings: Improve energy efficiency by minimizing friction losses.

Turbocharger Bearings: Offer high-temperature resistance and thermal shock resistance, boosting engine performance.

Corrosion-Resistant Pump & Valve Bearings: Suitable for harsh environments with strong acids or alkalis.

Nuclear Industry Bearings: Radiation-resistant and high-temperature-tolerant, used in nuclear reactor cooling systems.

Vacuum Robotic Arm Bearings: Non-magnetic and low outgassing, ideal for semiconductor wafer processing equipment.

High-Precision Measuring Instruments: Used in coordinate measuring machines (CMM) and optical instruments for ultra-precise operation.

Artificial Joints (e.g., Ceramic Hip Joints): Excellent biocompatibility and wear resistance, reducing risks of metal ion release.

Military/Defense: Missile guidance systems, drone bearings, etc.

High-Speed Centrifuges: Used in laboratory or industrial separation technologies, capable of withstanding ultra-high rotational speeds.

▼Technical Properties of Si3N4 Silicon Nitride Ceramic