Silicon nitride ceramic ball is a kind of precision ceramics sintered at high temperature in non-oxidizing atmosphere, with high strength, high wear resistance, high temperature, corrosion resistance, acid and alkali resistance and other excellent properties. Its density is 3.20g/cm³, about 1/3 of the weight of bearing steel, small centrifugal force when rotating, suitable for high-speed operation. In addition, silicon nitride ceramic balls are also self-lubricating, suitable for non-lubricating media and high pollution environment.

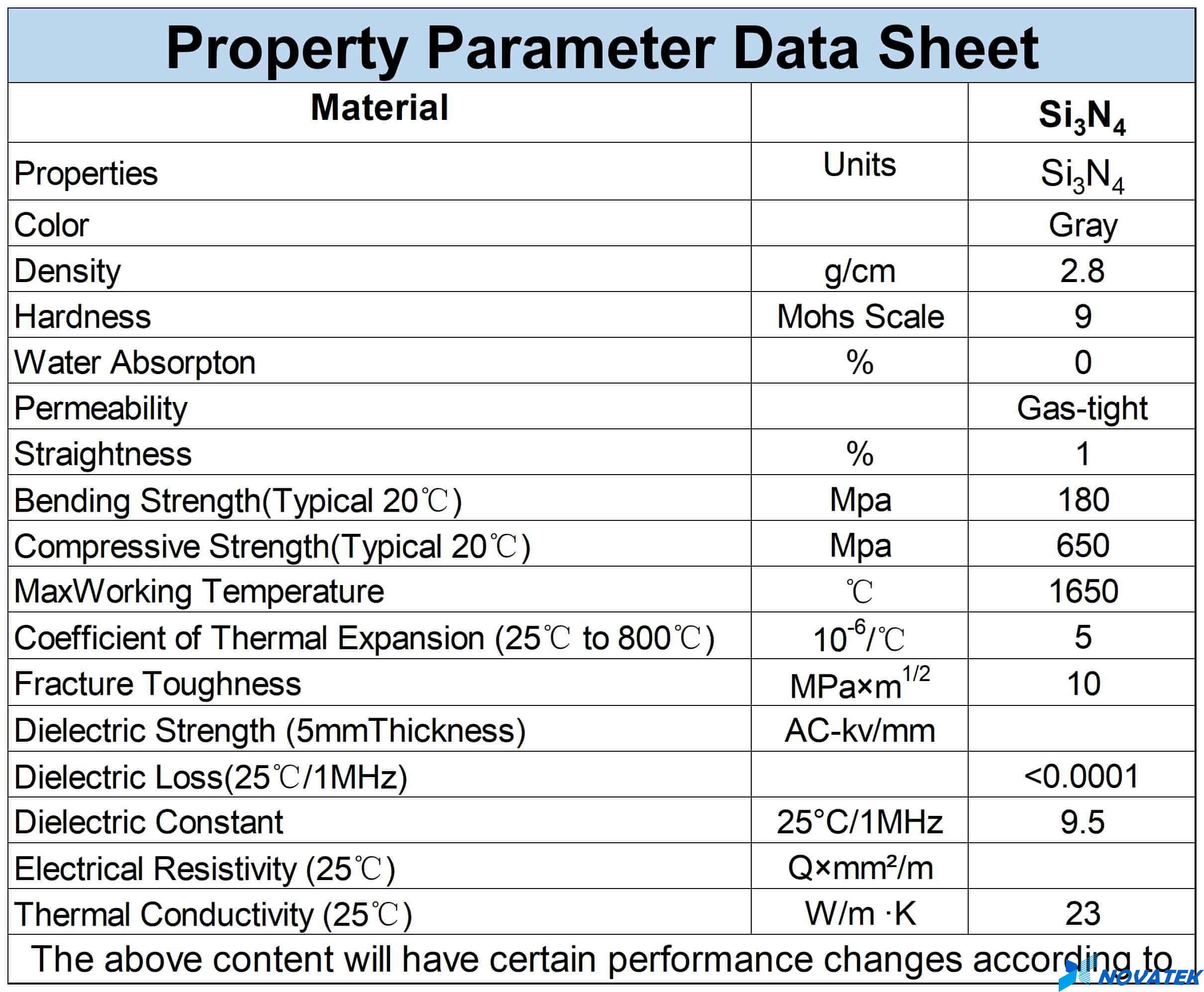

MATERIAL : Si3N4

DENSITY : 2.8

COLOR : Black / Blue / White

HRDNESS(Mohs scale) : 9

MAX WORKING TEMPERATURE : 1650

▼Performance characteristic

1.Small density, small centrifugal force, more conducive to high-speed operation

The density of silicon nitride ceramic material is about 3.2, while the density of steel bearing is about 7.8. The density of silicon nitride ceramics is only about 40% of the density of steel bearing. Therefore, when the rolling element uses silicon nitride ceramics, the bearing can effectively suppress the increase in the rolling element load caused by the centrifugal force when the bearing rotates at high speed. Therefore, the use of low-density silicon nitride balls is more conducive to the development of high-speed bearings.

2.Heat resistance, can adapt to higher temperature working conditions

Generally, when the operating temperature of steel bearings exceeds 120°C, the hardness will decrease and the rolling life will also decrease. For example: the service temperature limit of M50 high-temperature steel bearing is about 400℃. When this temperature is reached, the hardness of the steel decreases greatly. However, silicon nitride completely maintains its original hardness in this temperature range. Only at about 800℃, its hardness and strength began to decline. Therefore, for bearings used in high-temperature environments, silicon nitride materials are very suitable. For example: aviation jet engines, gas turbines, nuclear reactor systems, X-ray tube tungsten disks, and rockets and spacecraft.

3.small linear expansion coefficient, can be used in the field of environmental temperature changes

The linear expansion coefficient of silicon nitride is about 1/4 of that of steel bearing, so the dimensional change of silicon nitride bearing material with temperature changes is small.

Anti-locking: Therefore, the bearing made of silicon nitride ceramic material can effectively prevent the bearing material from "locking" due to temperature changes and dimensional changes. So as to ensure the stable operation of the equipment and reduce the loss due to equipment failure.

4.Excellent self-lubricating performance

Silicon nitride ceramic material itself has the functions of anti-friction, anti-wear and lubrication. Under bad lubrication conditions, such as oil-lean lubrication and oil-free dry friction, it shows superior anti-friction and self-lubricating performance. It has a good emergency state, which can effectively avoid losses caused by sudden equipment failures.

The self-lubricating mechanism of silicon nitride is still controversial. At present, some scholars believe that the main reason for this characteristic is that silicon nitride decomposes in a small amount during the friction process and forms a very thin film on the surface, thereby reducing the frictional resistance. And as the friction continues, the friction surface becomes more and more smooth, and the resistance becomes smaller and smaller, which has the effect of lubricating and reducing wear.

5.Stable chemical properties-corrosion resistance

Silicon nitride has good chemical resistance to most acids, such as hydrochloric acid, sulfuric acid, nitric acid, phosphoric acid and alkali. Only hydrofluoric acid or a mixture of hydrochloric acid and nitric acid can corrode silicon hydride.

Therefore, the bearing material made of silicon nitride can be exposed to corrosive acid, alkali, salt and other solutions for a long time. Compared with steel bearings, its average life will be 4-25 times longer than stainless steel bearings. It can be applied to machinery used in chemical machinery equipment, food, marine, sewage treatment and other departments to reduce the trouble caused by corrosion.

6.Non-magnetic, insulating

In a strong magnetic environment, when steel bearings are used, the fine powder worn down from the bearing itself is adsorbed on the rolling elements and rolling surfaces, which will become the main cause of early spalling damage and increased noise.

The use of bearing steel to prepare the bearings of the railway vehicle traction motor will cause electric corrosion, which will reduce the life of the traction motor bearing. The use of insulated full ceramic silicon nitride bearing materials can effectively improve the impact of electrical corrosion on the bearing.

▼Field of application

1. Mechanical field: silicon nitride ceramics are widely used in the mechanical field to manufacture valves, pipes, grading wheels, ceramic cutters, bearing balls, etc. Its low density, high temperature resistance, self-lubrication and corrosion resistance make it widely used in high-speed machine tool spindle high-speed bearing, aerospace engine, wind turbine bearing, automotive engine bearing and other equipment.

2. Semiconductor field: silicon nitride ceramic has excellent thermal conductivity and high thermal conductivity, making it an ideal material in semiconductor packaging field. Silicon nitride substrates have excellent performance in integrated circuits, high thermal conductivity, high bending strength and good thermal matching, suitable for high-performance power modules.

3. Bioceramic field: As a new generation of bioceramic materials, silicon nitride ceramic has good radiographic imaging performance, anti-infection performance and biocompatibility, and is widely used in biological sensors, spine, orthopedics and dental implants.

4. Wave transmitting material field: silicon nitride ceramics and their composite materials have excellent performances such as heat resistance, wave transmitting and bearing, and are used to manufacture high performance wave transmitting materials such as radome and antenna window.

Application Examples of Silicon Nitride Ceramics

5. Bearing: silicon nitride ceramic bearing ball has the characteristics of low density, wear resistance, high temperature resistance, corrosion resistance and self-lubrication, especially suitable for high-speed rotating bodies, such as high-speed bearing of high-speed machine tool spindle, aerospace engine bearing, etc.

6. Substrate: in the semiconductor field, silicon nitride substrate is widely used in packaging of high-performance power modules due to its high thermal conductivity, high bending strength and good thermal matching.

7. Implants: Silicon nitride ceramics are used in the biomedical field to manufacture spinal intervertebral fusion devices, orthopedic and dental implants, etc., with good biocompatibility and anti-infection performance.

Transparent material: silicon nitride ceramic and its composite materials are used to fabricate radome and antenna window, which have excellent transparent performance and high temperature resistance.

▼Technical Properties of Si3N4 Silicon Nitride Ceramic