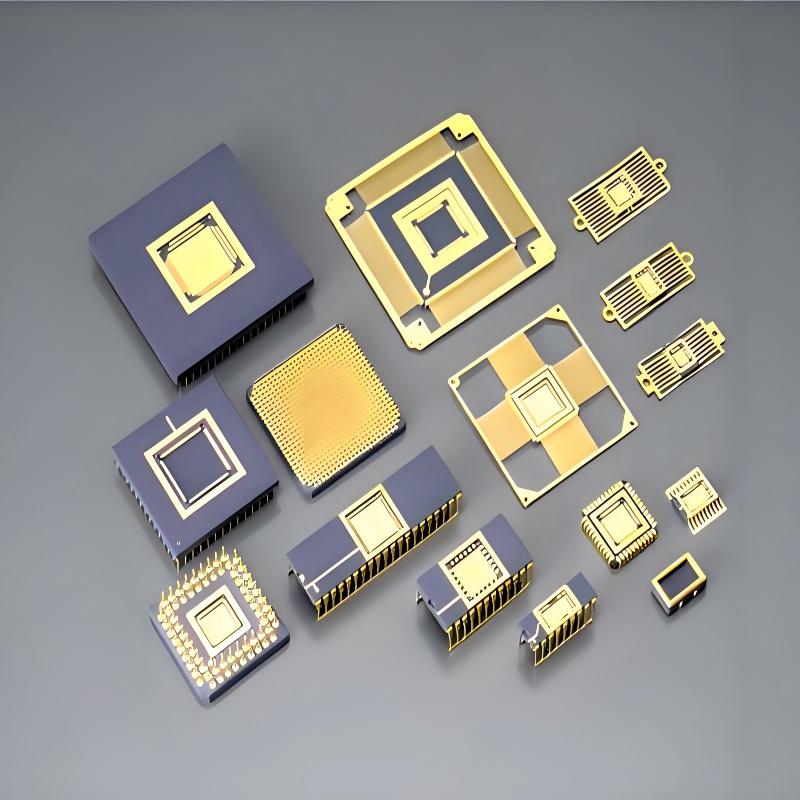

From LEDs to IGBTs: Customized ceramic substrates meet diverse power and size requirements

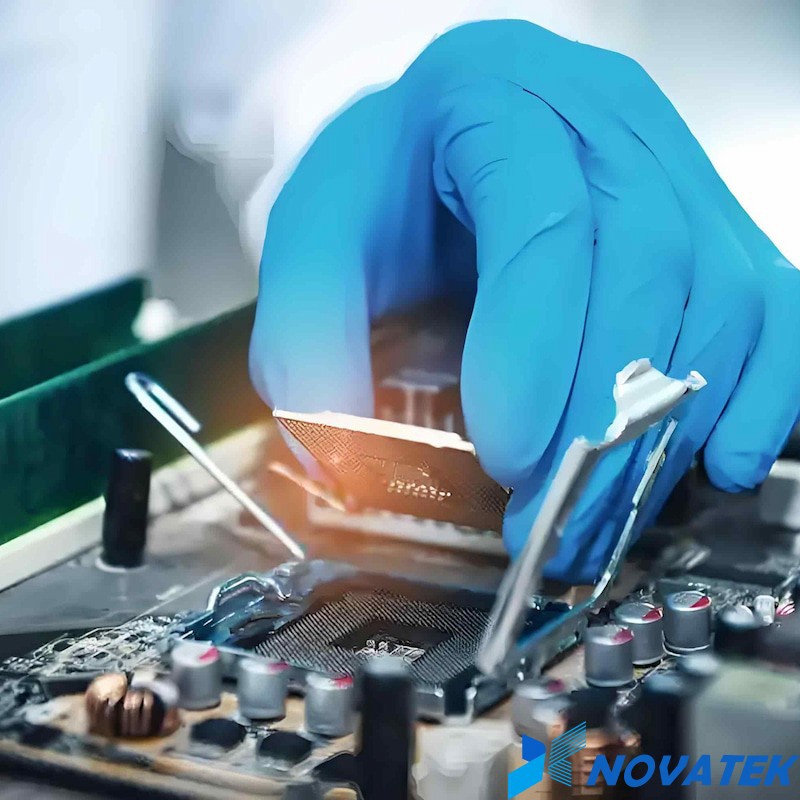

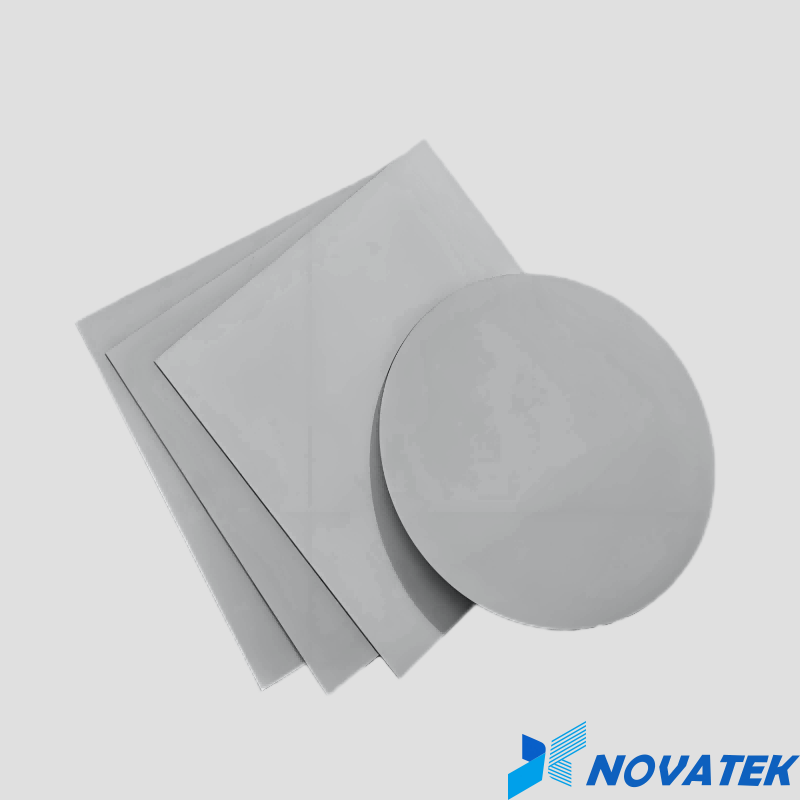

As being intelligence and electrification in various industries, ceramic substrates have become an indispensable foundational material in power electronics, semiconductor packaging, and microelectronics. These products act as key of electronic components, serving as packaging and interconnect materials used to support, connect, dissipate heat, and protect them. With independent R&D system and comprehensive production processes, novatekxm offers high-performance ceramic products for a variety of applications, including 96% aluminum oxide (Al₂O₃), aluminum nitride (AlN), zirconium oxide (ZTA), and silicon carbide (Si₃N₄) substrates.

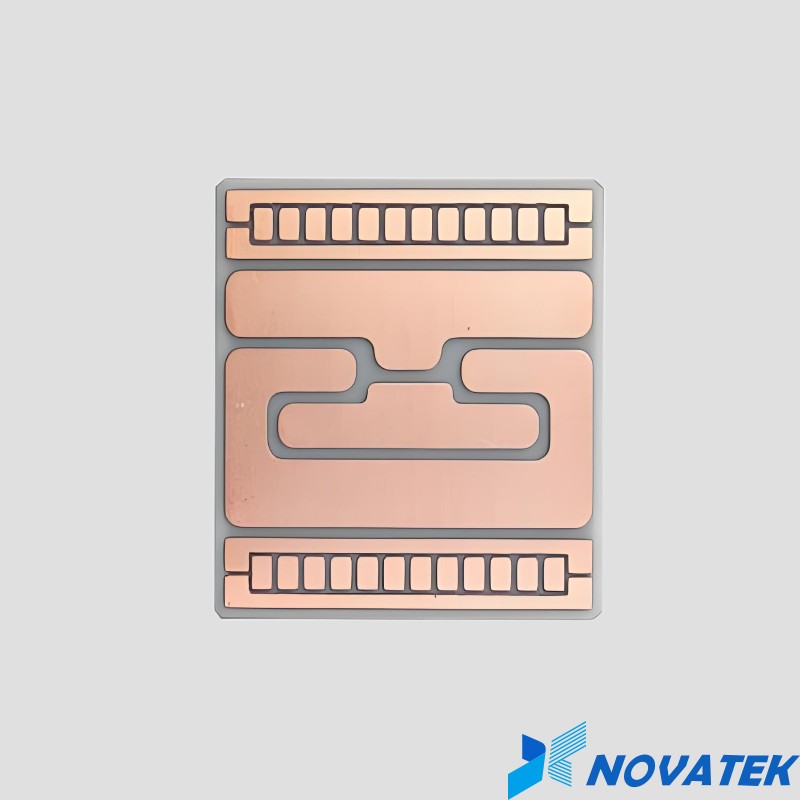

Multi-series product matrix, accurately matching diverse application needs

novatekxm provides ceramic substrates made of different materials to meet different customer applications:

1.96 Alumina (Al₂O₃)

Features: Low warpage, High thermal shock resistance, low warpage, high-temperature and resistant to acid and alkali corrosion, and excellent processability.

Applications: Thick/thin-film chip resistors, low-power LEDs, energy storage, and charging station substrates.

2. Aluminum Nitride (AlN)

Features: High thermal conductivity, high breakdown voltage and thermal expansion coefficient close to that of silicon wafers.

Applications: Heat sinks, High-power IGBT modules, high-power LEDs.

3. Zirconia Toughened Alumina (ZTA)

Features: High strength, high reflectivity, high thermal shock resistance, and excellent for processing.

Applications: Medium-power power modules, medium-power LEDs, and instruments.

4. Silicon Nitride (Si₃N₄)

Features: High thermal conductivity, high strength and toughness, coefficient of thermal expansion close to that of silicon wafers.

Applications: High-power IGBT modules, high-power heat sinks, and wireless modules.

Technological advantages across the entire industry chain, fully controlling the foundation of quality

1. Powder material is independent and controllable

novatekxm starts from the source, and its powder materials are independently controllable and of stable quality. The powder has high purity and low impurity content, which can realize batch production of powder, enhance stability, and better ensure the high consistency and stability of key parameters such as thermal conductivity and strength of the product.

2. Various molding processes

Proficient in various advanced ceramic forming technologies such as tape casting, dry pressing, isostatic pressing, etc., and able to select the most appropriate process according to the shape, size and performance requirements of the product, for better precision processing.

Specifications and dimensions:

Material

Unit

Al2O3

ZTA

AlN

Si3N4

Effective size(A、B)

mm

50.8-190

50.8-190

50.8-190

138*190

Thickness(T)

mm

0.25-1.5

0.25-1.5

0.25-1.0

0.25、0.32

Thickness Tolerance

mm

±5% (Min±0.03mm)

±5% (Min±0.03mm)

±5% (Min±0.03mm)

±5% (Min±0.03mm)

Warp(C)

mm

≤0.3%

≤0.3%

≤0.3%

≤0.3%

Surface Roughness

μm

0.2-0.6

0.2-0.5

0.2-0.75

0.2-0.75

Customizable in size, thickness, and surface roughness

Customizable in size, thickness, and surface roughness

3. Precision machining capabilities

Equipped with advanced equipment such as laser processing and grinding and polishing, it can achieve micron-level precision dimensional processing and ultra-low surface roughness (Ra value can reach nanometer level), meeting customers’ strict requirements for substrate shape, hole position and surface condition.

4.Strong independent R&D and customization capabilities

With more than 40 patents and contituing technical improvment, novatekxm’s R&D team can customize ceramic substrates with different thicknesses and performance parameters based on customers’ specific needs, providing one-stop solutions

5. Complete quality management system

With the IATF16949 automotive quality management system certification and a full-process quality control mechanism we are aimed to ensure that each substrate has stable performance and reliability. At the same time, we are equipped with a full range of precision testing and analysis instruments to assure high-standard quality.

Focusing on providing customers with a wide range of high-quality ceramic substrate products novatekxm offer one-stop ceramic substrate solutions, from standard parts to customized solutions. For more information on these products, please consult with info@novatekxm.com.

IPv6 network supported

IPv6 network supported